The first step for your electrical system is deciding on how large you want it to be amperage wise, and where all your equipment is going to go. If you have an AC system then you have to figure out where to put your batteries, which must be close to your inverter, which is close to the breaker panel/fuse box, etc. How can I have all of these in an accessible location?

The main parts you need are:

-An Inverter to convert the DC current in your batteries to AC

-A breaker panel/fuse box to be able to safely shut your lines down if you ever work on them or they short out. These come in many sizes and you pick yours based on how many lines you have. (How many runs - outlets and lights/switches connected together - you have)

-Batteries

-Ground wire to ground your inverter to the chassis of the vehicle [The wire size is determined by the output of your inverter. It's okay to go with a heavier wire.]

There are a lot of reasons why someone may or may not want an AC system, but if you do, then I hope you can learn from what I've learned and hopefully it helps you to be more comfortable with your own electrical system.

---

AC Equipment:

Breaker panel / AC Breakers:

A breaker is a switch that will shut off power to the line wired to that breaker. There are different types of breakers, and different sizes of panels, depending on how much power you want to supply to your truck. Most of the breakers in your panel at home are probably rated for 15 amps or 20 amps - this means that the maximum amount of current that can be supplied throughout that entire line is 15 amps, and if whatever is plugged into that line ever pulls more than 15 amps, it will "trip the breaker", meaning the breaker will flip off and cut the power to the line. Breakers are your main safety equipment for your electrical system. DC systems also use this idea, but they use fuses - which is essentially the same idea. There are also DC breakers called thermal breakers, and they work the same way as an AC breaker but are not manual; there is a small piece of metal inside a thermal breaker that warps when higher current passes through it, creating a break in the circuit. When it cools down after a couple minuets, the breaker connects again. AC breakers have to be manually switched over when they trip.

A 15 amp breaker will be wired to outlets and lights, and will use wire that is designed for carrying 15 amps worth of current - which is 14 gauge wire. 14 gauge wire can carry 15 amps safely, but if you wanted to use a 20 amp breaker, you would need to use a larger gauge of wire like 12 gauge to safely carry that extra amount of current. If you put a larger breaker on a smaller wire gauge, the wire heats up more than it's designed to inside your walls and could cause a fire.

Remember that anything wired to that breaker has a 15 amp limit - so if you had two outlets on that line and two appliances connected to each outlet, they have to "share" that 15 amp limit. You can't plug in an appliance that pulls 14 amps to one outlet and an appliance that pulls 5 amps on the other outlet on the same line at the same time because that's now pulling 19 amps and will trip the breaker, even though each appliance is under 15 Amps. This is why a lot of higher amperage appliances will have their own dedicated line - like a microwave or refrigerator.

Honestly, in a truck conversion you probably wouldn't need anything bigger than 15 amps, if you'd ever even need that. (Maybe if you only did one line in the whole truck.)

The normal max output of my inverter is 10 amps, but it can supply a 15amp draw (About 150% of it's capacity) for 1 minute before it faults(Turns off) after 1 minute. It can supply up to 31.25amps for 20 secs if needed. Even though that output is possible, anything over 15 amps will trip my breakers. If I tried to run a power tool that pulls more than 15 amps, the breaker on that line would trip immediately and disconnect the power before my inverter knew what happened. I overbuilt the electrical lines in my truck (having each line be 15amp supportive even though my inverter only puts out 10amps normally) for the ability to upgrade my inverter to something larger in the future if needed. Right now it's a minimal system, but I wouldn't have to re-wire everything if I do upgrade!

Most breaker boxes have a main breaker that shuts off the power entirely to all breakers, which is usually what "size" your breaker box will be. A common size for this is 125 Amps.

To put this amount of energy into perspective: 125 Amps x 120 Volts (AC Voltage) = 15,000 Watts. My laptop uses 60 Watts per hour, meaning I could run up to 250 laptops at once on that 125 Amp breaker. That's kinda overkill for any system you're putting in! You may never trip your main breaker, but it does give you a way to shut off all power to the breakers.

The output of my inverter is actually a GFCI outlet instead of hard wired - so I bought two of these appliance cords and wired them to the box with ring terminals.

|

| It was difficult to find a larger gauge cord that wasn't designed for a 220V appliance - I bought these on amazon. |

The top plug is direct wired to the right side of my breaker panel, and the bottom plug is the left side. If I wanted to cut the power, I could turn off the inverter and remove the plugs, or manually trip the internal breaker connected to the GFCI outlet and remove them, etc.

Inverters:

How an inverter works is that it takes the current and voltage from your batteries and adds a wave into the current to stabilize it. To create this wave uses extra power, and it increases the voltage of the line up to 120V. This is the basic premise of AC vs DC. There are two types of waves used with inverters, and thus two types of inverters: A Pure Sine wave and a Modified Sine Wave. The difference is the wave structure; A pure sine wave has a smoother curvature and is more efficient because it creates an easier structure for the current to follow and maintain a constant fluctuation vs a modified sine wave that looses some of the current through dissipation in the wire. This dissipation is called "noise" in the line and is why some people don't recommend you run sensitive equipment like computers on a Modified Sine Wave. This is worth some research by itself as the price difference between a pure sine wave and a modified sine wave is pretty big.

First and foremost, your inverter will always draw power, even if it's not converting power. That doesn't seem like a problem until you see that the average draw for inverters is 2 amps per hour - or there are efficiency ones where it only draws 1 amp (0.8per hour). That's 24amps a day just to be on! It uses more when it's actually converting. This could be a serious drawback if you plan on having a small battery system. That's also why a lot of RVers turn their inverter off at night. The output power of the inverter is usually associated with how much current it draws. A 3000Watt inverter is going to pull more than a 1500Watt.

If you're interested in a specific inverter, look in it's manual online for it's energy consumption. My inverter has two modes it can run in: A sleep/searching mode where it waits until it measures an attempt at current draw (I plugged in a toaster for example) and it will switch to converting mode if the draw is large enough, or it can just constantly convert and maintain current in the lines for me to use immediately.

In the manual for my inverter about it's sleep/searching mode: The Global LF Series is designed with extraordinarily low idle power consumption which is only a mere 0.8-1.8% of its rated power.

My inverter is a 1250Watt - so

1250 x 0.08 (0.8%) = 100

100/ 120(120Volts) = 0.83 Amps per hour

1250 x 0.01 (1%) = 12.5

12.5 / 120 = 1.041 Amps per hour

So it will use 0.8 - 1 amp an hour while in sleep mode (This is when it is continuously searching for a current in the line where it can switch over to conversion mode.)

The plus side is that almost everything we own runs on 120V AC, so it wouldn't be a lifestyle change in that regard. Appliances ranging from hair dryers to your espresso machine, you can use that. It would be just like your home - and some inverters allow you to connect straight to a 120V outlet to charge your batteries as it switches between bulk and trickle charge and monitors the charge. This also would let you plug a generator to it to charge your batteries. Inverters are expensive and I paid more for a refurbished one, but that was an important factor to me.

Types of Breakers:

So we know there are different amperage ratings for breakers, but there are also different types of breakers:

|

| Single 15Amp GE Brand Breaker |

This is probably the most common type of breaker: A single, normal width breaker takes one spot on the breaker panel and provides power to one line wired to it.

|

| Double 15Amp GE Brand Breaker |

A double breaker acts the same as a single in how it's mounted into the box, but has two lines coming off one connection. Cutting power off to one line will shut power off to the other; these are used for when you have limited space in the box, but are otherwise the same as a single. They have two separate lines that each have a 15amp limit, but the breaker would trip both lines if tripped. A double 15amp breaker is not equivalent to a 30amp breaker - remember that they are separate lines that share the same power input. That's all.

|

| A GFCI breaker |

A ground fault circuit interrupter breaker acts the same as a GFCI outlet. Instead of only tripping when the draw is higher than the amperage limit, it will also shut off the power if there is a short in the line. These are commonly used when you have a GFCI outlet on one of your lines, but you don't have to have a GFCI breaker if you use a GFCI outlet. The benefit of this breaker is that it will protect the entire line, whereas a GFCI outlet only shuts the power off at that location.

These three types are the most common you'll see, and the most common brand for sale is GE. There are older brands of breakers commonly found in homes like Siemens breakers, but some brands like Siemens are harder to find. Different brands of breakers could have different connection types on the breakers themselves where they connect into the breaker box. If you stick to the same brand, you shouldn't have a problem with connecting breakers into the box.

Initial Wiring For Breaker Panels:

There are at least three wires used in AC wiring: Black for positive, White for neutral, and Green for ground. The black wire brings the current to your outlet, the white neutral returns the current back to your neutral bar, and the ground wire is wired to the outlet and anything metal that could conduct electricity in case you have a short inside the outlet box (a spark etc). The ground wire forces the electricity to run back to your ground point in your breaker box instead of letting the current arc out into the air or something else in your living space.

|

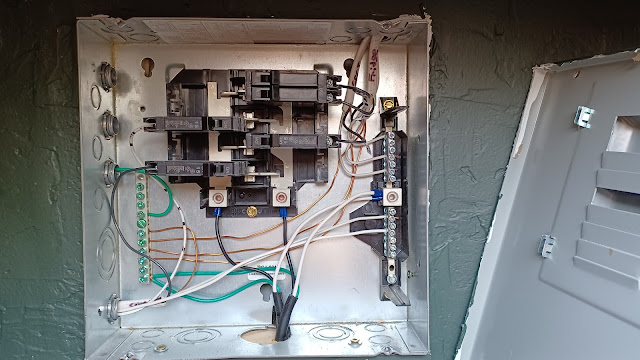

| My Breaker Panel: The middle is where the breakers clip into place, the bar on the right is my Neutral bar, and the green bar on the left is my Ground bar. |

When you buy your breaker box, it will come with the middle section where your breakers clip into place and a Neutral bar that's screwed in somewhere in the box (that large bar on the right-hand side is my neutral bar). These sub panels are usually an extension of your main breaker panel, so they don't usually come with a ground bar - and you have to buy this separately. You need a ground bar, commonly called a bus bar or terminal bar, and this should be screwed straight into the metal breaker panel. Ideally each breaker should have it's own grounding screw, but you can put multiple ground wires unto one screw if you need to. (I wouldn't put more than two though because of the wire diameter). I used a large green machine thread bolt to attach the grounding bar to the box, and then added a wide locking nut on the back that pins a grounding wire against the back of the panel that I attached to a metal stud in the truck to ground the entire panel.

The power coming into the box is your black wires, which screw into the terminals where the breakers are attached. The current then will flow through the metal plates you see in the middle - this is how power is supplied to all the breakers in the panel. The breakers hinge on the black plastic frame and then clip onto the metal plates in the middle.

A lot of the time breaker panels will have two terminals for the black wire, where each terminal powers each side of the panel, but you only have one black wire providing power. If this is the case, you would buy a bus bar / plate that would screw into those two terminal blocks and join them together. Then you can just attach the wire to the plate on either side and it would provide power to both. Ideally this would be a copper plate with a cover, but you have options.

The main incoming white / Neutral wire is wired to the main terminal block on the neutral bar, and the grounding wires can be placed anywhere on the grounding bar.

If you've looked into small breaker panels you've probably noticed they're commonly referred to as "sub panels". A home will usually have one main panel that provides power throughout the home, and if there was an addition to the house later on that only needed a couple more breakers, then people would buy a sub panel (essentially just a smaller sized breaker box). In homes sometimes people will "bond" their ground wires and neutral wires, meaning they wire them together, because their main breaker box already has the ground and neutral separated. I was confused at one point if I needed to bond my ground and neutral wires together, but because we only have one main breaker box in our truck, then we would wire them separately. Do not bond your ground and neutral wires together. In our case a sub panel works the same as your main breaker box - it's just a smaller version. Your black wire provides power directly to the breakers and the ground and neutral wires are separated into their own bus bars. If your outlet arcs for some reason, it would follow the ground wire through to your inverter, and then through the inverter ground to the chassis. I just wanted to throw this out there in case someone is wondering like I was; No, you do not bond them because this is your main power entry, your main breaker panel, so you want there to be a dedicated ground wire.

Another idea is grounding your electrical system. A "ground" is usually referred to as "earth ground", as in if your electrical system needs to discharge an arc (short, spark, etc) it would normally go through the ground wires in your breaker box, through your grounding wire to a metal rod that's pounded into the ground - the electricity is discharged into the earth. This is actually grounding something, and is why a lot of generators require you to use a grounding rod. Since your truck is isolated from the earth as your rubber tires don't allow chassis-to-earth contact, you can't actually ground your vehicle. Technically. I suppose you could connect a metal rod with wire to your chassis and actually ground it, but most people don't do this. If there was a lightening storm then I definitely want my electrical system isolated. A lot of people have worried that since the electricity can't discharge to the earth that it would make the chassis of your vehicle "live" as the electricity in the event of an arc would have nowhere to go, and it could shock someone if you touched the outside of your vehicle. Although the reasoning here is sound, the amount of current you would have in your electrical system should easily dissipate through your metal chassis if this ever happened, and it would only happen for maybe a millisecond. There is a large debate about this, and personally the only time you might want to worry about a short channeling through your chassis is if you have sensitive electrical equipment that is a part of your vehicle's engine. My 1997 truck has crank windows, so I'm not worried about any discharge affecting my equipment; A $100k sprinter van probably has more sensitive equipment that could be damaged in that type of event, but this is just speculation on my part. Most vehicles are "grounded" through the chassis, and work fine. This was a part of the reason why I isolated my indoor electrical systems from my engine systems, but that's up to you. I think you would be fine either way.

Connecting and Wiring Breakers:

So if you're wiring up a small project like mine, with maybe a 20 or 30 amp output max, then you're better suited to use a sub panel as your breaker box. You can absolutely do this, but you'll have to buy a separate ground bar (each line should ideally have it's own screw, but you can add max 3 wires to one screw - it depends on wire diameter and what can fit), and you'll probably want to add in your own cut-off switch or "main breaker". My "main breaker" is actually my inverter output, as it's a 20amp GFCI and I can also just unplug the wires to disconnect the power entirely. When you buy a normal breaker panel, it would have a singular larger breaker on the top, before the main wires feed the rest of the breakers, and that's the main breaker.

My panel is actually upside-down because my incoming wires had to come in from the bottom, if you're wondering why it looks a little weird. It does the job fine though!

Here is a close-up shot of the breakers in the breaker panel. The black wire (hot or positive wire) is stripped like you would for a normal outlet, about 1/4 inch of bare wire exposed, and is pushed into a little opening in the bottom of the breaker. Those screws on the bottom are then tightened down and hold that wire in place. If some of the wire is still exposed when pushed in, you can cut it shorter. Sometimes I would connect the wire first to make sure it's tight, then I would hook the breakers onto the black plastic and push them down onto the metal plates, locking them in place.

Each breaker, depending on the amp limit you set by breaker size, can power any number of outlets you wire to that breaker (up to that amperage limit), and this is called a "line". Each breaker has it's own line, which is one continuous wire from the breaker to however many outlets or switches you want to put on that line.

Every line has three wires; the positive, the neutral, and the ground. In a breaker panel, these wires from the outlets go through the side and are held in place with something called a knockout wire clamp.

Usually the sizes of knockouts are 1/2"inch or 3/8". Usually you would "knock" out the little metal disks to create a hole the wire can go through (and do this before you put your breaker box in - I used a flat head screwdriver and a hammer), and these clamps screw together from the inside and outside of the box. The larger diameter knockouts are to fit around conduit, in case you want to run your wires through that.

Wiring Outlets:

One of my most helpful books was this Black & Decker Home Wiring Book

First I decided on how many lines I should have in the truck, and there are certain rules that will help you decide: all large appliances that are electric should have their own dedicated line, like a fridge or a microwave. Any outdoor lights or lights in a wet environment should be on a line that has a GFCI wired in before that light, to protect that light. Most inverters have fault-protected outputs like a GFCI, that protects all of your lines, so you're covered in that case.

If you decide to use an electric cooktop, that would definitely be it's own line as well since it pulls a lot of power. In this case, that's at least 4 lines: Fridge, microwave, cooktop, and all your other outlets. Sometimes our kitchen appliances we use day-to-day have a higher draw than something we may use in our living room (a coffee maker verses a lamp for example), and all these combined may total more than 15amps. If you think you may use multiple items like this, at the same time, then you should make multiple lines instead of running all your outlets on one line. This would be the advantage to having multiple lines - I would recommend having at least two lines for your normal outlets so you don't have to worry about "where" or "when" to plug in and use your items.

No comments:

Post a Comment